Harvesting Cocoa

Pods containing cocoa beans grow from the trunk and branches of the cocoa tree. Harvesting involves removing ripe pods from the trees and opening them to extract the wet beans. The pods are harvested manually by making a clean cut through the stalk with a well sharpened blade. For pods high on the tree, a pruning hook type of tool can be used, with a handle on the end of a long pole. By pushing or pulling according to the position of the fruit, the upper and lower blades of the tool enable the stalk to be cut cleanly without damaging the branch that bears it.

The pods are opened to remove the beans within a week to 10 days after harvesting. In general, the harvested pods are grouped together and split either in or at the edge of the plantation. Sometimes the pods are transported to a fermentary before splitting. If the pods are opened in the planting areas, the discarded husks can be distributed throughout the fields to return nutrients to the soil.

The best way of opening the pods is to use a wooden club which, if it strikes the central area of the pod, causes it to split into two halves; it is then easy to remove the wet beans by hand. A cutting tool, such as a machete, is often used to split the pod, though this can damage the beans. Some machinery has been developed for pod opening, but smallholders in general carry out the process manually. After extraction from the pod, the beans undergo a fermentation and drying process before being bagged for delivery.

Fermentation

Fermentation can be carried out in a variety of ways, but all methods depend on removing the beans from the pods and piling them together or in a box to allow micro-organisms to develop and initiate the fermentation of the pulp surrounding the beans. The piles are covered by banana leaves.

The fermentation process begins with the growth of micro-organisms. In particular, yeasts grow on the pulp surrounding the beans. Insects, such as the Drosophila melanogaster or vinegar-fly, are probably responsible for the transfer of micro-organisms to the heaps of beans. The yeasts convert the sugars in the pulp surrounding the beans to ethanol. Bacteria then start to oxidise the ethanol to acetic acid and then to carbon dioxide and water, producing more heat and raising the temperature. The pulp starts to break down and drain away during the second day. In anaerobic conditions, the alcohol converts to lactic acid but, as the acetic acid more actively oxidises the alcohol to acetic acid, conditions become more aerobic and halt the activity of lactic acid. The temperature is raised to 40ºC – 45ºC during the first 48 hours of fermentation. In the remaining days, bacterial activity continues under increasing aeration conditions, as the pulp drains away and the temperature is maintained. The process of turning or mixing the beans increases aeration and consequently bacterial activity. The acetic acid and high temperatures kill the cocoa bean by the second day. The death of the bean causes cell walls to break down and previously segregated substances to mix. This allows complex chemical changes to take place in the bean such as enzyme activity, oxidation and the breakdown of proteins into amino acids. These chemical reactions cause the chocolate flavour and colour to develop. The length of fermentation varies depending on the bean type, Forastero beans require about 5 days and Criollo beans 2-3 days.

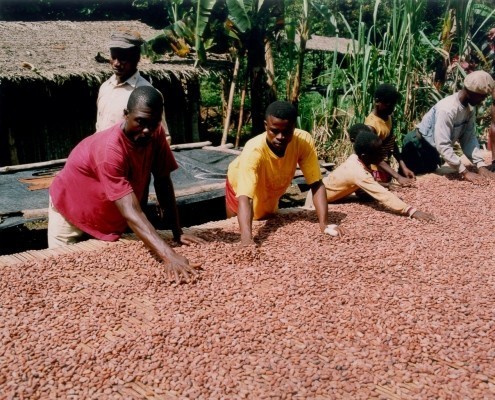

Drying Cocoa Beans

Cocoa beans are dried after fermentation in order to reduce the moisture content from about 60% to about 7.5%. Drying must be carried out carefully to ensure that off-flavorous are not developed. Drying should take place slowly. If the beans are dried too quickly some of the chemical reactions started in the fermentation process are not allowed to complete their work and the beans are acidic, with a bitter flavour. However, if the drying is too slow, moulds and off flavours can develop. Various research studies indicate that bean temperatures during drying should not exceed 65ºC.

There are two methods for drying beans – sun drying and artificial drying using wood and fuel dryers.